A spray dried dispersion (SDD) is a sophisticated formulation technique that involves the molecular dispersion of a drug within a polymer matrix, creating a homogenous mixture at the molecular level. This intricate formation process is achieved by first dissolving both the drug and the polymer in a suitable solvent. The solution is then subjected to a spray-drying process, which involves atomizing the solution into fine droplets and rapidly drying these droplets to form a solid dispersion. This method ensures that the drug is evenly distributed within the polymer matrix, enhancing its solubility and stability.

Why Spray Drying?

Significantly Improved Bioavailability of Poorly Soluble Compounds: One of the primary advantages of SDDs is the dramatic enhancement of the bioavailability of drugs that are poorly soluble in water. By dispersing the drug at a molecular level within a polymer, the surface area available for dissolution is greatly increased, leading to faster and more complete absorption in the body.

Consistent Particle Size Distribution: The spray-drying process allows for tight control over the particle size of the final product. This consistency in particle size distribution is crucial for ensuring uniform drug delivery and predictable pharmacokinetics, which is essential for maintaining therapeutic efficacy and patient safety.

Long-term Stability: SDDs provide long-term stability of the drug substance, protecting it from degradation due to environmental factors such as moisture, light, and temperature. The polymer matrix acts as a protective barrier, maintaining the integrity and potency of the drug over extended periods.

Increased Drug Loading Capacity: The technique allows for a higher loading of the drug within the polymer matrix compared to other formulation methods. This increased drug loading capacity can lead to smaller dosage forms, improving patient compliance and reducing manufacturing costs.

Potential for Taste Masking and Tailored Release Dosage Profiles: SDDs offer the flexibility to mask the unpleasant taste of certain drugs, making oral administration more palatable. Additionally, the release profile of the drug can be tailored to achieve immediate, delayed, or sustained release, depending on the therapeutic needs and the properties of the drug-polymer combination.

Tightly Controlled and Optimized for Each Compound: The formulation process of SDDs is highly customizable and can be precisely controlled to optimize the performance of each specific drug compound. This ensures consistent quality and performance, meeting stringent regulatory standards and delivering reliable therapeutic outcomes.

Scalability from Pilot to Full Commercial Production: SDD technology is highly scalable, allowing for seamless transition from small-scale pilot production to full-scale commercial manufacturing. This scalability is crucial for the efficient development and commercialization of new drug products, reducing time-to-market and production costs.

Versatile Formulation Options: SDDs offer a range of versatile formulation options, including dry powders, granules, or as part of a composite particle system. This versatility provides flexibility in downstream processing and dosage form design, enabling the development of various drug delivery systems such as tablets, capsules, and inhalable powders

Spray Drying Development Capabilities

Thorough Analytical and Physical Characterization

In the context of spray drying, thorough analytical and physical characterization is essential to ensure the quality, efficacy, and stability of the final product. This process involves a multifaceted examination of the chemical, physical, and biological properties of the spray-dried particles.

Chemical Characterization

Chemical characterization of spray-dried products involves sophisticated analytical techniques to identify and quantify the components. High-performance liquid chromatography (HPLC) is employed to separate, identify, and quantify each component in the spray-dried mixture. Mass spectrometry (MS) is used to determine the molecular weight and structure of the compounds, providing insights into the purity and composition of the spray-dried particles. Nuclear magnetic resonance (NMR) spectroscopy offers detailed information about the molecular structure and dynamics, which is crucial for understanding the chemical interactions within the spray-dried product. Additionally, techniques like ultraviolet-visible (UV-Vis) spectroscopy, infrared (IR) spectroscopy, and gas chromatography (GC) are used to further analyze the chemical composition and ensure the integrity of the spray-dried product.

Physical Characterization

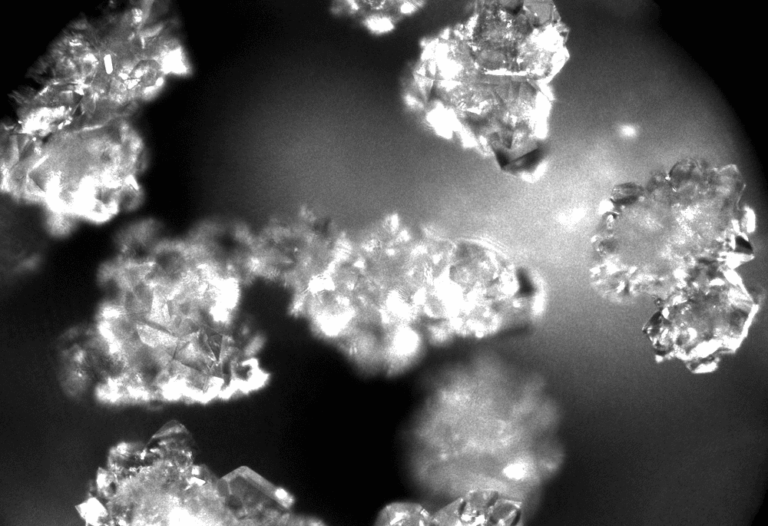

Physical characterization involves a detailed assessment of properties such as particle size distribution, polymorphism, crystallinity, hygroscopicity, and thermal behavior. Particle size distribution is critical as it affects the dissolution rates and bioavailability of the spray-dried product. Techniques like laser diffraction and dynamic light scattering (DLS) are used to measure particle size and distribution. Polymorphism is studied to identify different crystalline forms that may have varying stability and solubility. X-ray diffraction (XRD) and differential scanning calorimetry (DSC) are employed to analyze the crystalline structure and thermal behavior of the spray-dried particles. Hygroscopicity, the ability of a substance to absorb moisture from the environment, is analyzed using techniques like dynamic vapor sorption (DVS) to understand its impact on stability and handling. Thermogravimetric analysis (TGA) is used to study the thermal behavior and stability of the spray-dried product under different temperature conditions.

Pre-formulation Testing, Formulation, and Process Development

Pre-formulation testing, formulation, and process development are critical phases in the creation of spray-dried pharmaceutical products. These stages focus on understanding the properties of the drug substance and designing a suitable delivery system to optimize therapeutic outcomes.

Pre-formulation Testing

During the pre-formulation stage, extensive studies are conducted to assess the solubility, permeability, and stability of the drug under various environmental conditions. Solubility studies involve determining the drug’s ability to dissolve in various solvents, which is essential for selecting appropriate formulation strategies. Permeability testing, often conducted using cell culture models such as Caco-2 cells, evaluates the drug’s ability to cross biological membranes, predicting its absorption in the human body. Stability studies, including forced degradation and photostability testing, assess the drug’s resistance to chemical degradation over time.

Formulation Development

Formulation development involves selecting appropriate excipients, the inactive ingredients that aid in the drug’s delivery, stability, and manufacturability. Excipients such as polymers, surfactants, and stabilizers are chosen to enhance the stability and bioavailability of the spray-dried product. The formulation process includes designing various dosage forms such as tablets, capsules, injectables, and transdermal patches, considering factors like dosage accuracy, patient compliance, and manufacturing feasibility. Spray drying parameters such as feed concentration, atomization, and drying temperature are optimized to produce a consistent and high-quality spray-dried product.

Process Development

Process development is the stage where scalable and reproducible manufacturing processes are developed, optimized, and validated to ensure consistent quality and performance of the final product. This involves detailed studies on mixing, granulation, drying, compression, and coating processes. In the context of spray drying, process parameters such as inlet temperature, outlet temperature, feed rate, and atomization pressure are carefully controlled to achieve the desired particle size, morphology, and moisture content. In-process controls and analytical methods are developed to monitor and ensure product quality throughout the manufacturing process.

Processing Using Organic and Aqueous Solvents to Produce Particles with Optimal Stability and Absorption Characteristics

Spray drying can utilize both organic and aqueous solvents to produce particles with optimal stability and absorption characteristics. The choice of solvent and the method of particle production significantly impact the particle size, shape, and crystalline form of the spray-dried product.

Organic Solvents

Organic solvents such as ethanol, methanol, acetone, and dichloromethane are often chosen for their ability to dissolve a wide range of compounds, aiding in the purification and recrystallization processes. These solvents are particularly useful for processing hydrophobic drugs that have low solubility in water. The use of organic solvents in spray drying can enhance the solubility and bioavailability of poorly soluble drugs by producing amorphous solid dispersions (ASDs). ASDs are characterized by their high surface area and improved dissolution rates, which can lead to enhanced absorption and therapeutic efficacy.

Aqueous Solvents

Aqueous solvents, primarily water, are preferred for their safety, environmental friendliness, and ability to solubilize polar compounds. Water-based spray drying is suitable for processing drugs intended for human consumption, as it eliminates the need for toxic organic solvents. The use of aqueous solvents can also produce particles with desirable properties such as high porosity, low density, and controlled release characteristics. Spray drying with aqueous solvents is commonly used for producing inhalable powders, injectable formulations, and oral dosage forms.

Research and Development (R&D) and Current Good Manufacturing Practice (cGMP) Manufacturing Capabilities, Covering Early Development to Early Clinical Trial Supply (Phase 1 and 2a)

Research and development (R&D) and current Good Manufacturing Practice (cGMP) manufacturing capabilities are fundamental components in the pharmaceutical industry, ensuring that new drug candidates are developed and produced to the highest standards from early development through to early clinical trial supply (Phase 1 and 2a).

Research and Development (R&D)

R&D activities for spray drying involve discovering and optimizing new drug candidates, conducting preclinical studies, and developing initial formulations suitable for spray drying. This includes laboratory research to identify promising drug molecules, followed by in vitro and in vivo studies to assess their pharmacokinetics, pharmacodynamics, and toxicity profiles. The formulation is optimized to enhance the solubility, stability, and bioavailability of the drug using spray drying technology.

cGMP Manufacturing

The transition from R&D to cGMP manufacturing involves scaling up the spray drying process to ensure reproducibility and compliance with regulatory standards. cGMP manufacturing capabilities encompass the infrastructure, equipment, and processes required to produce pharmaceutical products in compliance with regulatory standards set by agencies such as the FDA, EMA, and WHO. This includes maintaining controlled environments with appropriate cleanroom classifications, implementing rigorous quality control measures to monitor critical process parameters and product attributes, and ensuring traceability and documentation throughout the manufacturing process. Early clinical trial supplies produced using spray drying are manufactured under cGMP conditions to ensure consistent quality and safety.

Downstream Processing Technologies: Granulation, Roller Compaction, Tableting

Spray drying can be integrated with downstream processing technologies such as granulation, roller compaction, and tableting to produce final dosage forms. These downstream processes are essential for converting the spray-dried powder into a suitable dosage form for patient administration.

Granulation

Granulation involves the agglomeration of spray-dried particles to improve their flow properties and compressibility. This process can be achieved through wet granulation, where a liquid binder is added to the spray-dried powder, or dry granulation, where the powder is compacted under pressure. Granulation enhances the uniformity and consistency of the final product, ensuring accurate dosing and patient compliance.

Roller Compaction

Roller compaction is a dry granulation technique that involves compressing the spray-dried powder between two counter-rotating rollers to form ribbons or flakes. These ribbons are then milled to produce granules with improved flowability and compressibility. Roller compaction is particularly useful for moisture-sensitive drugs, as it eliminates the need for liquid binders and drying steps.

Tableting

Tableting is the final step in the downstream processing of spray-dried products, where the granules are compressed into tablets using a tablet press. This process involves optimizing parameters such as compression force, tablet weight, and hardness to produce tablets with the desired characteristics. Tableting ensures that the spray-dried product is delivered in a convenient and patient-friendly dosage form.

Innovations and Advanced Techniques in Spray Drying

Recent advancements in spray drying technology have further enhanced its precision, reliability, and applicability in pharmaceutical formulations. These innovations include novel nozzle designs, process optimization, and the use of advanced materials and techniques.

Novel Nozzle Designs

Innovative nozzle designs have been developed to improve control over droplet size and morphology, resulting in highly uniform particles. These cutting-edge nozzles allow for better customization of particle properties, optimizing drug delivery systems and improving patient outcomes.

Process Optimization and Monitoring

Advancements in process optimization and monitoring have played a crucial role in enhancing spray drying technology. Real-time monitoring of critical process parameters, such as temperature, humidity, and particle size, ensures consistent product quality and performance. Process analytical technology (PAT) tools are employed to monitor and control the spray drying process, enabling rapid adjustments and optimization.

Advanced Materials and Techniques

The use of advanced materials and techniques has expanded the applications of spray drying in pharmaceuticals. For example, the incorporation of polymeric and lipidic excipients has enabled the production of amorphous solid dispersions, enhancing the solubility and bioavailability of poorly soluble drugs.

Late-Phase Spray Drying Capabilities

Formulation and Process Optimization:

Our scientists can refine your formulations to enhance the stability, efficacy, and bioavailability of pharmaceutical products. Our process optimization capabilities ensure that each step in the manufacturing process is fine-tuned for maximum efficiency, reducing waste and improving product quality. Advanced analytical techniques are employed to monitor and adjust critical process parameters, ensuring that every batch meets stringent quality standards.

Processing Molecules Using Organic and Aqueous Solvents:

Hycon is adept at handling a wide range of chemical entities, utilizing both organic and aqueous solvents to process active pharmaceutical ingredients (APIs). The ability to switch between different solvent systems allows for greater flexibility in formulation development, accommodating the unique properties of each molecule. Both of our state-of-the-art facilities are equipped with sophisticated solvent recovery systems, minimizing environmental impact and ensuring regulatory compliance.

Integrated Teams and Streamlined Processes for Smooth Transfer and Scale-Up:

Hycon employs integrated teams composed of experts from various disciplines, including chemistry, engineering, regulatory affairs, and quality assurance, to ensure a holistic approach to tech transfer and scale-up. Streamlined processes are designed to facilitate seamless communication and collaboration between departments, reducing the risk of errors and delays. Comprehensive project management tools and methodologies are utilized to track progress, manage resources, and ensure that timelines and budgets are adhered to.

cGMP Manufacturing from Phase 3 to Commercial Scale:

Hycon operates under current Good Manufacturing Practices (cGMP), ensuring that all products are manufactured to the highest quality standards. Our facilities are designed to scale production seamlessly from Phase 3 clinical trials to full commercial manufacturing, ensuring consistency and reliability at every stage. Rigorous quality control measures are in place to ensure that each batch meets regulatory requirements and customer specifications.

Flexibility to Handle Diverse Programs:

We handle a wide range of pharmaceutical programs, from orphan drugs, which serve small patient populations, to pediatric variants that require specialized formulations and dosing. We are also equipped to handle blockbuster products, which demand high-volume production and stringent quality control. This adaptability allows Hycon to meet the needs of various clients, regardless of the complexity or scale of the project.

A Comprehensive Range of Equipment:

Hycon boasts an extensive array of advanced granulators, blenders, tablet presses, and encapsulators, capable of accommodating various finished dosage forms. The diverse equipment lineup ensures that they can produce a wide range of products, from tablets and capsules to powders and granules. This versatility in manufacturing capabilities allows for customized solutions tailored to the specific needs of each client, ensuring optimal product performance and patient outcomes.

Related Services

FAQs

Here are some frequently asked questions about Spray Drying

Spray drying is a method used to produce a dry powder from a liquid by rapidly drying with a hot gas. This process involves atomizing the liquid into a fine mist and then exposing it to a flow of hot air, causing the solvent to evaporate quickly and leaving behind dry particles. Spray drying is widely used in the pharmaceutical industry to improve the solubility and bioavailability of drugs, create stable powders for formulation, and enable the production of inhalable aerosols.

Spray drying is important in pharmaceuticals for several reasons:

- Enhances Drug Solubility: Many active pharmaceutical ingredients (APIs) have poor water solubility, which can be improved through spray drying, enhancing their bioavailability.

- Particle Size Control: It allows precise control over particle size and distribution, critical for consistent drug delivery, especially in inhalation therapies.

- Stability: Spray drying can increase the stability of sensitive compounds by rapidly removing moisture and reducing exposure to heat.

- Formulation Flexibility: Enables the production of various dosage forms, including powders, capsules, and tablets, by incorporating excipients during the drying process.

Spray drying can process a wide range of materials, including solutions, suspensions, and emulsions containing APIs, excipients, and other pharmaceutical ingredients. It is suitable for heat-sensitive compounds due to the rapid evaporation of solvent, minimizing thermal degradation. Spray drying can also handle materials that require specific particle characteristics, such as porosity, density, and surface morphology, for targeted drug delivery applications.

Yes, spray drying can significantly improve the bioavailability of drugs. By converting poorly soluble drugs into amorphous solid dispersions with enhanced dissolution rates, spray drying can increase the rate and extent of drug absorption in the body. This process is particularly beneficial for BCS Class II drugs, which have high permeability but low solubility.

Our spray drying services offer comprehensive capabilities, including:

- Development and optimization of spray drying processes tailored to specific API properties and formulation requirements.

- Scalability from pilot-scale batches for feasibility studies and clinical trials to full-scale commercial production.

- Particle engineering to achieve desired particle size, morphology, and physicochemical properties.

- Encapsulation of volatile or sensitive compounds to enhance stability and control release.

- Analytical support for characterizing spray-dried products, including particle size distribution, moisture content, and thermal properties.

We can handle a broad range of spray drying operations, from small-scale pilot projects for early-stage development and clinical trial materials to large-scale commercial production. Our facilities are equipped with state-of-the-art spray dryers that can be adjusted to accommodate different batch sizes, throughput requirements, and product specifications, ensuring flexibility and scalability to meet our clients' needs.

We ensure the quality of spray-dried products through stringent quality control measures and adherence to Good Manufacturing Practices (GMP). This includes:

- Raw material inspection to verify purity and compliance with specifications.

- Process monitoring and control using advanced instrumentation to maintain optimal drying conditions.

- In-process testing to assess critical quality attributes such as moisture content and particle size.

- Final product testing to confirm compliance with all specifications and regulatory requirements.

- Documentation and traceability of all manufacturing and testing activities.

Yes, spray drying can be used to develop controlled release formulations. By encapsulating the API within a matrix of polymer or other excipients that control the release rate of the drug, spray drying can produce particles that release the drug over a desired time frame. This technique is useful for both immediate-release and sustained-release formulations, offering flexibility in drug delivery strategies.

Our spray drying services comply with all relevant regulatory standards, including those set by the Food and Drug Administration (FDA), European Medicines Agency (EMA), and International Council for Harmonisation (ICH) guidelines for pharmaceutical manufacturing. We ensure that our processes, equipment, and facilities meet the stringent requirements for GMP compliance, ensuring the highest level of quality and safety for all spray-dried products.

We handle heat-sensitive compounds by optimizing the spray drying process to minimize thermal exposure. This can involve adjusting the inlet and outlet temperatures, feed rate, and atomization parameters to ensure rapid solvent evaporation without compromising the integrity of the heat-sensitive compound. Additionally, we can use cryogenic spray drying or employ protective excipients that encapsulate and shield the compound from heat. Our expertise in process development allows us to tailor the drying conditions to the specific thermal sensitivity of each compound, ensuring its stability and activity.