Highly flexible and help you meet required drug delivery profiles, incorporating taste-masking and modified release, multiple-dose ranges and ease of administration while focusing on patient centricity.

Overview

- Innovative Oral Delivery: Multiparticulate dosage forms are tiny granules or pellets that encapsulate active pharmaceutical ingredients (APIs), offering a modern approach to oral drug delivery.

- Drug Release: These small units, also known as multiparticulates, can be tailored for controlled, delayed, or targeted drug release depending on the polymer employed in fabrication. They are known under many terminologies such as multiple units, pellets, beads, granules, micro-granules, spheroids, or mini- or micro-tablets.

- Clinical Advantages: These forms are designed to optimize drug release, enhance bioavailability, and improve patient adherence through features like taste masking and reduced gastrointestinal irritation.

- Flexible dose delivery

- capsules

- sachets

- sprinkles

Allows for a wide range of customized release profiles within a single capsule and precise delivery at lower dosage strengths through a range of tablet sizes.This range allows for a titration of a broader range of dosages

Multiparticulate system with release-controlling polymers

- Functional membranes are applied to 1.0-2.0 mm cylindrical tablets to control release rates

- The small size facilitates the development of products that can offer multiple drugs or varying release profiles within a single capsule

- High drug-loading capability with the possibility to combine with a high-density formulation for high-strength formulations

Advantages

Multiparticulate dosage forms are seeing increasing use in the pharmaceutical industry to enable modified release, high dose, and age-appropriate dosage forms. Here are some reasons why they are significant:

- Versatility in Drug Release: Multiparticulate systems can be engineered to release drugs at specific sites within the gastrointestinal tract. This targeted delivery is achieved through the application of pH-sensitive coatings or other release-controlling polymers that respond to the varying environments along the GI tract.

- Enhanced Stability: The encapsulation of APIs in multiparticulate units can protect sensitive compounds from degradation, enhancing the stability of the formulation. This is particularly beneficial for drugs that are susceptible to hydrolysis or oxidation.

- Reduced Risk of Dose Dumping: Unlike single-unit dosage forms, multiparticulates reduce the risk of dose dumping, where the entire dose is released at once, potentially causing adverse effects. The distribution of the API across multiple particles allows for a more controlled and gradual release.

- Combination Therapies: Multiparticulate systems are ideal for combination therapies, where two or more APIs can be delivered simultaneously with different release profiles. This can simplify medication regimens and improve treatment outcomes.

- Modified Release Profiles: The ability to modify the release profile of drugs is a significant advantage of multiparticulate systems. By altering the composition and thickness of the coatings, formulators can create immediate-release, delayed-release, or extended-release profiles within the same dosage form.

- Multiple-Dose Ranges: Multiparticulate systems allow for a wide range of dosing options. The dose can be easily adjusted by changing the number of particles, making it possible to tailor the medication to the specific needs of the patient.

These advantages make multiparticulate dosage forms a promising area of R&D in the pharma industry, particularly for serving special populations such as pediatric and geriatric patients.

Patient Centricity

Ease of Administration: Multiparticulate systems can be administered in various forms, such as capsules, sachets, or sprinkles, offering flexibility and convenience for patients. This is especially important for populations with special dosing requirements, such as children and the elderly.

Flexible Dose Titration: The design of multiparticulate systems facilitates dose titration, allowing healthcare providers to fine-tune the dosage based on the patient’s response to the medication.

Taste-Masking: One of the key challenges in oral drug delivery is the bitter taste of many APIs. Multiparticulate systems address this issue by incorporating taste-masking technologies, such as coating the particles with sweeteners or flavors, to improve the palatability of the medication.

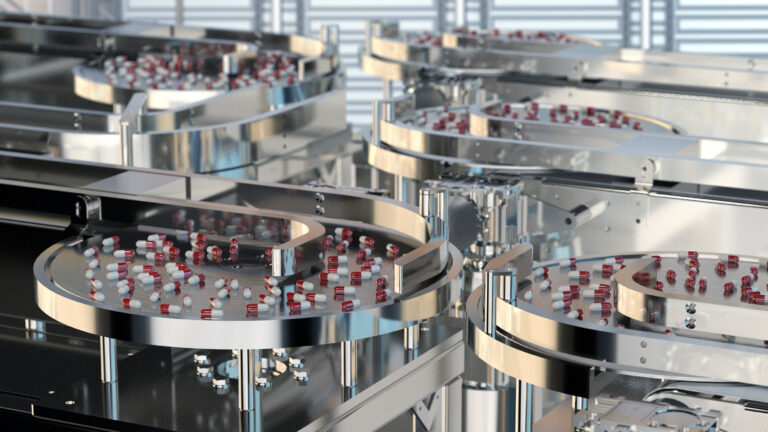

Manufacturing

- Advanced Technologies: We use techniques such as fluid bed coating, extrusion-spheronization, and miniaturization to create multiparticulates that meet stringent quality standards.

- Patient-Centric Design: Our dosage forms are crafted with the patient in mind, focusing on ease of administration, improved compliance, and adaptable dosing for various patient groups

- Scalable Production: From small-scale batches for clinical trials to large-scale commercial manufacturing, our facilities are equipped to handle diverse production demands with agility and precision.

- Techniques: We use state-of-the-art manufacturing processes, including high-shear granulation and Wurster coating, to produce multiparticulates with controlled release profiles.

Delve deeper into the manufacturing process:

- Formulation of Multiparticulates: The multiparticulates are prepared by various methods like pelletization, granulation, spray drying, and spray congealing. The active pharmaceutical ingredient (API) is incorporated into these multiparticulates to form the core. Our team develops multiparticulate formulations with precision, ensuring each pellet carries the exact dose required for therapeutic efficacy.

- Drug Layering: This process involves the application of the drug onto the core multiparticulates. The drug can be applied as a powder, solution, or suspension layer. The goal is to achieve a uniform layer of the drug on each multiparticulate. The monomers are dissolved in two separate phases, which are emulsified to reach the desired particle size. The monomers polymerize at the interface of the emulsion droplets, thereby encapsulating the drug.

- Coating: After drug layering, a coating is applied to the multiparticulates. The coating can serve various purposes such as controlling the drug release rate, protecting the drug from the environment, or masking the taste of the drug. The coating process can be carried out using techniques like fluid-bed coating. Coatings are applied for many reasons, e.g. improving product appearance, making swallowing easier, and modifying drug release.

- Encapsulation: The coated multiparticulates are then encapsulated. Encapsulation can be done using hard shell capsules, sachets, or by compressing into tablets. This step helps in dose precision and ease of administration.

- Packaging: The final step is packaging the encapsulated multiparticulates. The packaging materials and machinery used are important to ensure the stability and integrity of the dosage forms during storage and transportation.

Each of these steps requires careful control of various parameters to ensure the quality and performance of the final product. It’s important to note that the exact process can vary depending on the specific requirements of the drug being formulated.

Formulation Development

Manufacturing Process

- Initial API Assessment: Rigorous analysis of the active pharmaceutical ingredient (API) to determine its compatibility with multiparticulate formulation.

- Excipient Synergy: Selection of excipients that not only complement the API but also enhance the overall multiparticulate system.

Advanced Granulation Techniques

- High-Precision Granulation: Utilizing both wet and dry granulation methods to achieve the perfect balance between particle size and uniformity.

- Extrusion-Spheronization: Crafting uniform, spherical multiparticulates with a high degree of control over size and shape.

Coating Application

- Precision Fluid Bed Coating: Implementing both top-spray and bottom-spray fluid bed coating techniques for uniform and consistent application.

- Innovative Wurster Coating: Utilizing the Wurster process for precision coating, ensuring even distribution and optimal drug release profiles.

Drying and Maturation

- Optimized Drying Protocols: Carefully controlled drying processes to achieve the desired final moisture content without compromising the multiparticulate integrity.

- Curing: Allowing multiparticulates to mature under controlled conditions, solidifying the coating and stabilizing the release mechanism.

Related Services

FAQs

Here are some frequently asked questions about Multiparticulate

Multiparticulate drug delivery systems are advanced pharmaceutical formulations composed of multiple, small particulate entities. These systems can include mini-tablets, microspheres, microgranules, or pellets, each capable of delivering active pharmaceutical ingredients (APIs) in a controlled manner. Multiparticulates offer several advantages, including enhanced bioavailability, reduced side effects, and improved patient compliance by enabling flexible dosing and targeted drug delivery to specific areas of the gastrointestinal tract.

Multiparticulate systems improve patient compliance through several mechanisms. Firstly, their small size and flexible dosing options make them easier to swallow compared to larger tablets or capsules, which is particularly beneficial for pediatric and geriatric patients. Additionally, they can be designed to release the drug in a controlled manner, minimizing the frequency of dosing and reducing the likelihood of side effects. This tailored release profile also allows for the combination of multiple APIs within a single dosage form, simplifying complex medication regimens.

Multiparticulate drug delivery systems are versatile and can be used across a wide range of therapeutic areas. Key applications include modified release formulations where a prolonged therapeutic effect is desired, targeted drug delivery for local action in specific regions of the gastrointestinal tract, and combination therapies where multiple APIs are delivered using a single dosage form. These systems are also used in pediatric formulations, offering dose flexibility and improved palatability.

Yes, multiparticulate systems are highly versatile and can be engineered to achieve both immediate and controlled release formulations. Immediate release multiparticulates are designed to disintegrate quickly upon administration, ensuring rapid absorption of the API. Controlled release formulations, on the other hand, employ various coating technologies and matrix materials to modulate the release rate of the API, allowing for sustained drug levels in the bloodstream over an extended period.

Manufacturing multiparticulate systems involves various technologies, including fluid bed coating, extrusion-spheronization, spray drying, and hot melt extrusion. Fluid bed coating is commonly used for applying functional coatings to pellets or granules to control the release of the API. Extrusion-spheronization is a technique for forming uniformly sized pellets. Spray drying and hot melt extrusion are used to create solid dispersions, enhancing the solubility and bioavailability of poorly water-soluble drugs.

Renejix ensures the quality and consistency of multiparticulate formulations through rigorous quality control (QC) measures and Good Manufacturing Practices (GMP). This includes the use of high-quality raw materials, validated manufacturing processes, and comprehensive testing of the final product for parameters such as particle size distribution, drug content uniformity, and release characteristics. Stability testing is also conducted to ensure the product maintains its intended efficacy and safety profile throughout its shelf life.

Regulatory considerations for multiparticulate drug delivery systems include ensuring compliance with guidelines set forth by regulatory bodies such as the FDA (U.S. Food and Drug Administration) and EMA (European Medicines Agency). This involves submitting detailed data on the formulation's composition, manufacturing process, quality control tests, and clinical data demonstrating its safety and efficacy. Specific considerations might include the evaluation of the system's bioequivalence to existing therapies and the assessment of any novel excipients or technologies used in the formulation.

Yes, multiparticulate systems are particularly well-suited for tailoring to the specific needs of pediatric and geriatric patients. Their small size and the possibility to incorporate taste-masking technologies make them easier to swallow and more palatable for children. For geriatric patients, the flexibility in dosing and the ability to combine multiple APIs can help manage polypharmacy issues, making it easier to adhere to complex medication regimens.

Multiparticulate systems address the challenge of poorly water-soluble drugs through several formulation strategies, such as the use of solid dispersions, lipid-based formulations, and nanotechnology. These approaches can significantly enhance the solubility and, consequently, the bioavailability of hydrophobic drugs. Solid dispersions, for example, involve dispersing the drug in a polymer matrix to improve dissolution rates, while lipid-based formulations can enhance absorption by facilitating the drug's transport across biological membranes.

Renejix can provide comprehensive support in the development of multiparticulate drug delivery systems, including formulation development, process optimization, scale-up, and manufacturing. This support encompasses the selection of suitable excipients, the design of the drug release profile, and the application of appropriate coating technologies. Additionally, Renejix can offer analytical and regulatory services to ensure the formulation meets all quality standards and regulatory requirements, facilitating a smooth path to market approval.