Customized Solution Design: Offering tailor-made approaches for unique product challenges, including solubility enhancement through nanomilling, targeted drug delivery, and stability optimization through advanced moisture control techniques.

Expert DEA Navigation: Our teams are experts in navigating U.S. Drug Enforcement Administration Controlled Substances. This ensures compliance and seamless handling for both tablets and capsules, specializing in schedules II-V controlled substances.

Robust Global Supply Chain: Leveraging a vast network of manufacturing facilities equipped with automated packaging lines, real-time inventory management systems, and integrated supply chain solutions, we ensure consistent and reliable global distribution of solid oral dose products.

FAQs

Here are some frequently asked questions about Process Technologies

Our CDMO offers a comprehensive range of processing technologies for pharmaceutical product development. These include, but are not limited to, milling, granulation, blending, compression, encapsulation, coating, and packaging. We also specialize in the development and manufacturing of oral solid dosage forms (OSDFs), including tablets, capsules, powders, granules, and oral films.

We ensure the quality and reliability of our processing technologies through a combination of factors. Firstly, we adhere to strict regulatory standards such as Good Manufacturing Practices (GMP) and Good Laboratory Practices (GLP). Secondly, we invest in state-of-the-art equipment and technology, including modern milling, granulation, and tablet manufacturing machinery. Thirdly, we have highly trained and experienced staff who follow standardized operating procedures and undergo regular training to stay updated with the latest advancements in the field.

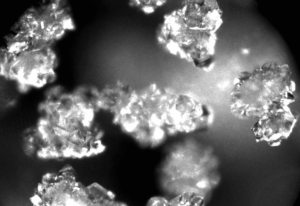

Our milling capabilities include both wet and dry milling technologies. Wet milling is used to reduce particle size and improve solubility by creating a suspension of the active ingredient in a liquid medium. Dry milling is used to achieve particle size reduction and uniformity in the solid-state. We employ a range of milling equipment, including hammer mills, jet mills, and ball mills, to achieve the desired particle size distribution.

Granulation is a critical step in OSDF development as it helps improve flow properties, compressibility, and uniformity of the formulation. We employ both wet and dry granulation techniques, such as high shear granulation, fluid bed granulation, and roller compaction. Our approach to granulation is customized based on the specific needs of the formulation, taking into consideration factors like particle size, density, and drug release profile.

We utilize a variety of blending technologies to achieve homogeneity in our formulations. These include V-blenders, double cone blenders, and ribbon blenders, among others. For compression, we use high-speed tablet presses equipped with different tooling configurations to produce tablets of various shapes, sizes, and compositions. Our compression technologies ensure uniformity and consistency in tablet hardness, weight, and drug content.

Tablet coating is an important step in the manufacturing of coated tablets, which provide several benefits, including improved stability, taste masking, and protection against moisture and light. We employ various coating technologies, including pan coating, fluid bed coating, and spray coating. We ensure the uniformity of tablet coating by controlling the coating solution's viscosity, spray rate, drying temperature, and air volume, among other parameters.

Encapsulation is a process used to encapsulate active ingredients within a protective shell. Our CDMO offers various encapsulation technologies, including hard gelatin capsule filling, soft gelatin capsule filling, and powder encapsulation. We have the capacity to encapsulate a wide range of formulations, including liquids, suspensions, and powders, and can customize capsule sizes and shapes to meet client specifications.

Packaging plays a critical role in the safety and stability of pharmaceutical products. Our packaging processes adhere to strict GMP standards, and we conduct regular quality control checks to ensure the integrity and durability of packaging materials. We also employ technologies such as blister packaging, bottle filling, and pouching to protect products from environmental factors and ensure accurate dosing and tamper-evident packaging.

Yes, we offer specialized processing technologies for controlled-release formulations, including sustained-release and extended-release formulations. These include matrix tablets, reservoir systems, osmotic pumps, and coated pellets, among others. We work closely with clients to develop custom-tailored formulations that meet specific release profiles and duration requirements.

Due to confidentiality agreements, we cannot disclose specific client projects. However, we have successfully partnered with numerous pharmaceutical companies to develop and manufacture a wide range of products, including immediate-release and controlled-release formulations, novel oral dosage forms, and combination therapies. Our expertise in processing technologies has enabled us to meet the diverse needs of our clients and achieve successful outcomes.