The selection of an appropriate dosage form is paramount. This choice is important because it directly influences the effectiveness, safety, and the extent to which patients adhere to their prescribed medication regimens. Dosage forms, which range from tablets and capsules to more advanced systems like transdermal patches and oral films, serve as vehicles for delivering drugs to the body.

Their design is meticulously engineered to ensure that medication is released at the right rate, absorbed efficiently, and targeted precisely where needed. Understanding and selecting the right dosage form is therefore essential for achieving optimal therapeutic outcomes and enhancing patient well-being.

Meaning of Dosage Forms

Dosage forms refer to the means by which drug substances are delivered to the body to achieve therapeutic effects. These forms are meticulously designed to ensure that the active ingredient is released in a manner that maximizes efficacy while minimizing side effects.

The selection of an appropriate dosage form is critical, as it influences the drug’s absorption, distribution, metabolism, and excretion. Dosage forms include solids (tablets, capsules), liquids (solutions, suspensions), semisolids (creams, ointments), and others like transdermal patches and inhalers.

Each form is tailored to specific patient needs, conditions, and routes of administration, playing an important role in the success of medical treatments by enhancing patient compliance, convenience, and overall therapeutic outcomes.

Important Types of Dosage Forms

Understanding the various types of dosage forms is important in pharmaceutical science, as it directly impacts drug efficacy, safety, and patient compliance. From oral solids and liquids to transdermal patches and semi-solids, each dosage form is designed to optimize medication delivery and therapeutic outcomes.

Oral Solids

Oral solid dosage forms, including tablets, capsules, and powders, stand as the cornerstone of pharmaceutical delivery systems due to their widespread acceptance, convenience, and versatility. These forms are favored for their stability, facilitating extended shelf life and ease of transport.

Tablets and capsules, in particular, offer unparalleled precision in dosing, a critical factor in ensuring therapeutic efficacy. The manufacturing process of oral solids has evolved, allowing for the incorporation of advanced techniques such as controlled-release mechanisms. This innovation permits the gradual release of medication, enhancing its absorption and ensuring a steady therapeutic effect over an extended period.

Moreover, oral solids can be engineered to bypass the digestive system’s harsh environment, protecting sensitive drug molecules until they reach the site of absorption. This is achieved through various formulations, including enteric-coating or encapsulation within specially designed capsules. Such developments have significantly improved the bioavailability of certain medications, making oral solids a versatile option for a wide range of therapeutic areas.

It is pertinent to note that the results indicate tablets as the most favored oral dosage form at 58%, followed by liquids at 20%, and capsules at 11%.

Oral Suspensions and Solutions

Oral suspensions and solutions are liquid dosage forms that play a vital role in pharmaceutical therapy, especially for individuals who encounter difficulties swallowing solid medications, such as children and the elderly. These formulations offer a solution by providing a more palatable and easier-to-swallow alternative.

Oral solutions are clear liquids where the medication is completely dissolved, ensuring uniformity in dose. Suspensions, on the other hand, consist of finely divided drug particles dispersed throughout a liquid carrier, requiring agitation before administration to ensure dose consistency.

One of the primary advantages of oral suspensions and solutions is the flexibility in dosing they offer. Unlike solid forms that come in fixed doses, liquids can be easily measured to accommodate specific dosing requirements, making them ideal for pediatric dosing where precision is important. Moreover, these liquid forms can be flavored and sweetened to enhance palatability, significantly improving patient compliance.

Formulating oral suspensions and solutions also allows for the inclusion of solubilizing agents and stabilizers, which can enhance the solubility of drugs that are poorly soluble in water. This is particularly important for achieving adequate absorption and therapeutic efficacy. Additionally, the liquid form enables faster onset of action compared to solids, as the drug is already in a form that is more readily absorbed by the body.

However, oral liquids do present challenges, such as the potential for microbial growth, necessitating the addition of preservatives. Stability can also be a concern, as some compounds may degrade more rapidly in solution. Despite these challenges, oral suspensions and solutions remain indispensable in the pharmaceutical arsenal, offering a combination of dosing flexibility, enhanced palatability, and the potential for improved drug absorption, thereby ensuring that patients of all ages receive effective and reliable treatment.

Softgel Capsules

Softgel capsules represent a unique and innovative dosage form within the pharmaceutical landscape, offering distinct advantages over traditional solid and liquid forms. These capsules consist of a soft, gelatin-based shell surrounding a liquid or semi-solid fill, which can contain a variety of active pharmaceutical ingredients.

The flexibility in formulation afforded by softgels is particularly beneficial for drugs with poor solubility in water, as the liquid fill can incorporate solubilizers and other excipients that enhance the drug’s bioavailability.

One of the most significant benefits of softgel capsules is their ability to improve patient compliance. The soft, flexible shell makes them easier to swallow than hard tablets or capsules, and the potential for masking unpleasant tastes and odors further enhances their acceptability. Additionally, the encapsulation of the drug in a liquid medium can facilitate a faster onset of action, as the drug is already in a form that is easier for the body to absorb.

Softgel capsules also provide a high degree of dose uniformity and precision, ensuring that each capsule delivers the exact amount of medication required. This precision, combined with the enhanced bioavailability and patient-centric design, makes softgels an essential dosage form for a wide range of therapeutic applications.

Despite their many advantages, the production of softgel capsules requires specialized manufacturing processes and equipment, which can increase production costs. However, the value they add in terms of improving drug efficacy, enhancing patient compliance, and expanding formulation possibilities justifies the investment, making softgels a popular choice among pharmaceutical developers and patients alike. The global softgel capsules market was valued at approximately USD 7.67 billion in 2022 and is projected to reach USD 8.21 billion by the end of 2023.

Semi-Solids

Semi-solid dosage forms, including creams, ointments, gels, and pastes, are pivotal in topical therapeutic applications, targeting the skin or mucous membranes directly. These formulations are designed to deliver active pharmaceutical ingredients (APIs) at the site of action, minimizing systemic exposure and associated side effects. The choice between these semi-solid forms depends on the drug’s physicochemical properties, the desired release rate, and the condition being treated.

Creams are emulsions that typically blend oil and water, offering a non-greasy feel that is easily absorbed by the skin, making them suitable for moist or weeping lesions. Ointments, with their higher oil content, provide a more occlusive barrier, enhancing drug penetration and hydration for dry, scaly conditions.

Gels, formed from water or alcohol and thickening agents, offer a cooling effect and are preferred for their ease of application and quick drying properties, ideal for hairy areas or acne treatment. Pastes, containing a higher proportion of solid particles, form a protective layer that is especially beneficial for protecting and soothing inflamed skin areas.

The formulation of semi-solids is a complex science, aiming to achieve the optimal consistency, stability, and drug release profile. Excipients play an important role, influencing the viscosity, spreadability, and absorption of the active ingredient. Additionally, semi-solids must be designed to maintain their integrity and efficacy under various storage conditions.

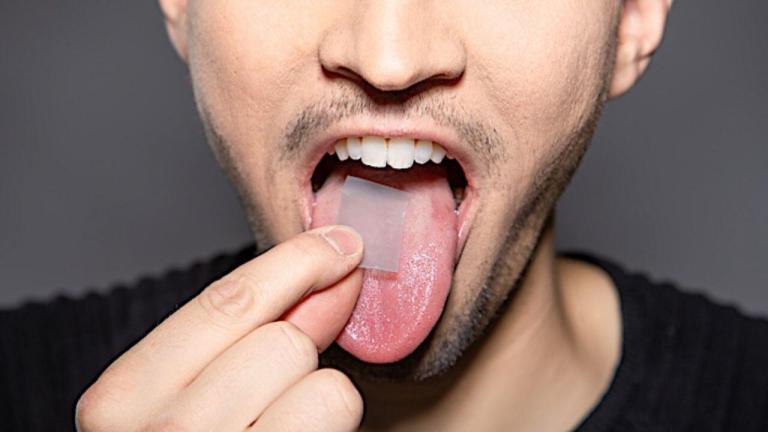

Oral Films

Oral films represent a cutting-edge advancement in pharmaceutical dosage forms, offering a discreet, convenient alternative to traditional oral medications. These thin, flexible strips are designed to dissolve rapidly when placed on the tongue or inside the cheek, facilitating quick drug absorption directly into the bloodstream through the mucous membranes. This innovative delivery method bypasses the gastrointestinal tract, potentially reducing the impact of first-pass metabolism and enhancing bioavailability for certain drugs.

Oral films are particularly beneficial for patients who experience difficulty swallowing pills, such as children, the elderly, and those with dysphagia, improving patient compliance and acceptance. The compact, portable nature of oral films makes them ideal for on-the-go medication administration without the need for water, further enhancing their convenience.

The formulation of oral films involves sophisticated technology to incorporate active pharmaceutical ingredients into a thin film matrix while maintaining the drug’s stability and efficacy. Flavoring agents can also be added to improve taste, making medication administration more palatable.

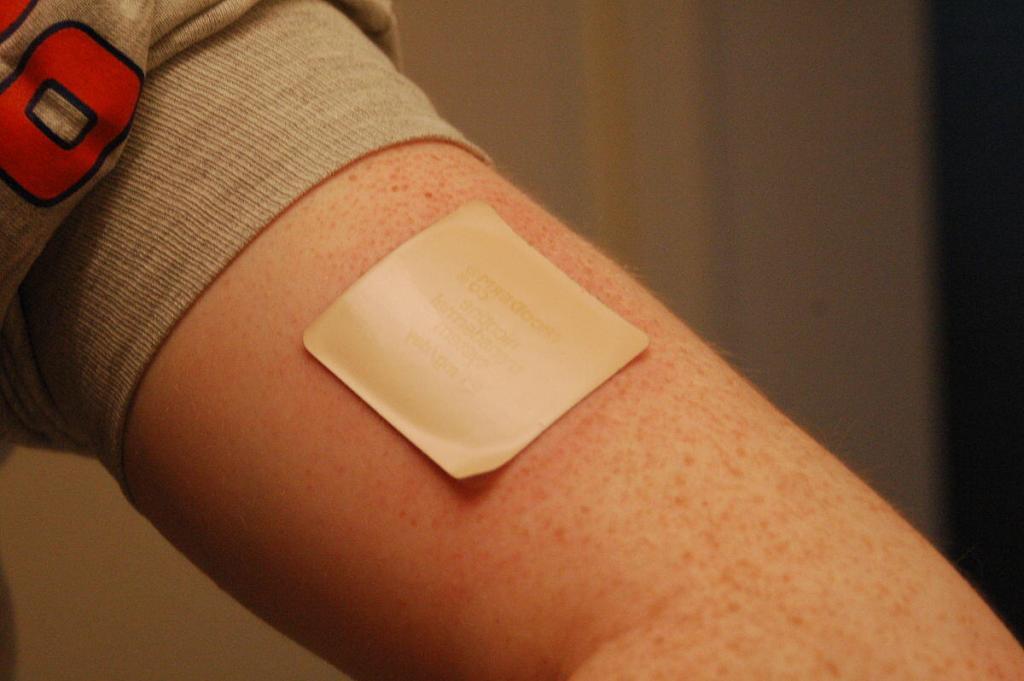

Transdermal Patches

Transdermal patches are a sophisticated dosage form designed for the systemic delivery of drugs through the skin, offering a controlled and sustained release over extended periods.

This method of administration is particularly advantageous for medications that require steady plasma concentrations to achieve optimal therapeutic effects. By bypassing the gastrointestinal tract and first-pass metabolism in the liver, transdermal patches can enhance bioavailability and reduce the potential for gastrointestinal side effects.

The design of transdermal patches involves a backing layer, a drug reservoir or matrix containing the active pharmaceutical ingredient, a rate-controlling membrane (in some designs), and an adhesive layer that secures the patch to the skin. This multi-layered structure allows for the precise control of drug release rates, ensuring consistent drug delivery over days or even weeks.

Transdermal patches are favored for their ease of use, improved patient compliance, and the ability to terminate drug delivery quickly by simply removing the patch. They are ideal for patients who have difficulty swallowing pills or those who require long-term medication management, such as chronic pain, hormonal therapies, and cardiovascular treatments.

However, formulating transdermal patches requires careful consideration of the drug’s molecular size, solubility, and skin permeability. Enhancers may be used to improve drug absorption, but skin irritation at the site of application can be a concern. Despite these challenges, transdermal patches represent a valuable and innovative approach to drug delivery, expanding the possibilities for treatment and patient care.

How These Types of Dosage Forms Differ

The types of dosage forms differ primarily in their physical state, route of administration, release mechanisms, patient acceptability, and therapeutic application. Here’s a breakdown of their key differences:

| Dosage Form | Physical State | Route of Administration | Release Mechanisms | Patient Acceptability | Therapeutic Application |

| Oral Solids (Tablets, Capsules) | Solid | Oral | Varies (immediate, extended, delayed release) | High (swallowing difficulties for some) | Broad, for systemic effects |

| Oral Suspensions & Solutions | Liquid | Oral | Generally, immediate release | High (flexible dosing, easy for difficulties swallowing) | Local (e.g., cough) and systemic effects, pediatric and geriatric use |

| Softgel Capsules | Soft, flexible shell with liquid or semi-solid | Oral | Enhances bioavailability through improved solubility | High (easy to swallow, taste masking) | Lipophilic drugs, drugs requiring solubilization |

| Semi-Solids (Creams, Ointments, Gels) | Semi-solid | Topical or rectal | Localized action; controlled release possible | Varies (non-invasive, texture dependent) | Localized conditions, skin disorders, pain relief |

| Oral Films | Thin, flexible film | Oral mucosal (sublingual or buccal) | Rapid dissolution and absorption through mucosa | High (convenient, for those with swallowing difficulties) | Fast onset, systemic and local effects |

| Transdermal Patches | Patch with drug reservoir or matrix | Transdermal | Controlled, sustained release over days/weeks | High (convenient, non-invasive; skin irritation possible) | Chronic conditions, steady medication levels needed (e.g., pain, cardiovascular diseases) |

How Dosage Forms are Manufactured?

Manufacturing dosage forms involves specific processes tailored to each form.

Tablets, for instance, are typically made through compression and can be coated or uncoated. Capsules, on the other hand, are created by coating the drug substance and dry ingredients around a seed material. Both tablets and capsules contain active pharmaceutical ingredients (APIs) and dry powder ingredients. These processes ensure the accurate and safe delivery of medication to patients, meeting stringent quality and safety standards.

The manufacturing process begins with the selection and testing of raw materials, including APIs and excipients. These materials are then processed according to strict guidelines in facilities that adhere to Good Manufacturing Practices (GMP). After formulation, the dosage forms undergo rigorous testing for quality, potency, and purity.

Once approved, they are packaged and distributed to pharmacies, hospitals, and other healthcare providers. Throughout the manufacturing process, stringent quality control measures are implemented to ensure the final product meets regulatory requirements and is safe for patient use. The projected growth of the global oral solid dosage contract manufacturing market is substantial, with an estimated increase from USD 5.4 billion in 2023 to USD 36 billion by 2035. This growth represents a compound annual growth rate (CAGR) of 4.6% over the forecast period from 2023 to 2035.

Final Words

Selecting the appropriate dosage form is a critical decision that hinges on the drug’s characteristics, the intended therapeutic effect, and the specific needs of the patient. This choice is instrumental in maximizing drug efficacy, ensuring safety, and promoting patient compliance. Advances in pharmaceutical technology continue to play an important role in the development of innovative dosage forms, offering more personalized and effective treatment options.

By leveraging these technological advancements, healthcare professionals can tailor treatments to individual patient profiles, significantly enhancing therapeutic outcomes. The ongoing evolution of dosage forms underscores their fundamental importance in the successful delivery of medical treatments, marking a cornerstone in the advancement of modern medicine.