Integrated On-Demand Clinical Manufacturing

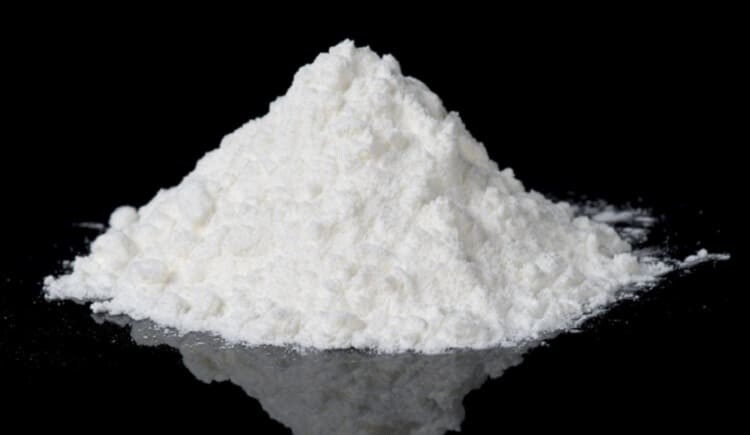

Clinical manufacturing, also known as clinical trial material (CTM) manufacturing, is the specialized production of pharmaceuticals intended for use in clinical trials. These pharmaceuticals are used in clinical research to assess their safety and efficacy before they are approved for commercial use. This process is distinct from commercial manufacturing due to its unique requirements and smaller scale.

Our integrated on demand manufacturing and infrastructure is designed to streamline the path from development to delivery, ensuring that your clinical trials and commercial launches are supported by the highest quality manufacturing processes.

Overview

- State-of-the-Art Equipment Utilization: Our clinical manufacturing prowess is anchored in the utilization of cutting-edge equipment. This allows us to procure, blind, and distribute small molecule oral dosages with unmatched precision and adaptability, catering to the specific needs of clinical trials.

- Expert Blinding Services for Clinical Trials: We offer specialized blinding services in clinical manufacturing, ensuring that every challenge, no matter how complex, is met with a solution that maintains the integrity and confidentiality of the clinical trials.

- Packaging: Our dedicated team of packaging experts in clinical manufacturing is committed to resolving any challenge. We guarantee that our packaging solutions uphold the highest standards, contributing to the success of clinical trials.

- Seamless Technology Transfers: Our clinical manufacturing processes are designed for seamless technology transfers. This ensures a smooth transition from development to production, maintaining consistency and quality throughout the lifecycle of the product.

- Dosage Form Design: In clinical manufacturing, we design dosage forms that not only enhance bioavailability but also improve patient compliance. Our designs are patient-centric, ensuring ease of use and effectiveness.

- Comprehensive Bioavailability Assessment: As part of our clinical manufacturing services, we conduct thorough bioavailability assessments. This critical step confirms the efficacy of our pharmaceutical products and their ability to meet therapeutic needs.

- Rapid Scale-Up Capabilities: Our clinical manufacturing facilities are equipped for rapid scale-up, allowing us to meet the increasing demands of clinical trials efficiently and effectively, while maintaining the highest quality standards.

- Advanced Blinding Techniques: We employ advanced blinding techniques in clinical manufacturing to maintain the integrity of double-blind studies. This is crucial for achieving unbiased clinical trial outcomes and ensuring the reliability of study results.

- Automated Over-Encapsulation Services: Our clinical manufacturing includes state-of-the-art automated over-encapsulation services. This ensures that trial medications are indistinguishable from placebos, maintaining the study’s blind.

- Full-Spectrum Clinical Manufacturing Services: From small-scale pilot batches to full-scale production, our services are designed to support all phases of clinical trials, ensuring flexibility and scalability.

- Advanced Blending, Granulation, and Encapsulation: Our clinical manufacturing expertise extends to advanced blending, granulation, and encapsulation services. These processes are critical for creating high-quality, consistent pharmaceutical products.

- High-Speed Capsule Manufacturing with Precision: Our clinical manufacturing includes high-speed capsule manufacturing with 100% weight checking. This ensures precision and quality in every capsule we produce.

- Customized Capsule Fills for Clinical Trials: We provide customized capsule fills in clinical manufacturing, including hard gelatin capsules. This flexibility allows us to meet the diverse needs of clinical trials and patient populations.

Tailored Solutions for Clinical Manufacturing

- Comprehensive Formulation Development in Clinical Manufacturing: Our clinical manufacturing expertise is exemplified in our comprehensive formulation development. By leveraging a profound understanding of the physicochemical properties of drugs, we ensure that each product achieves optimal bioavailability and stability.

- Seamless Technology Transfers Within Clinical Manufacturing: At the heart of our clinical manufacturing process is the specialization in seamless technology transfers. This critical aspect guarantees that the journey of your product from research and development to commercialization is executed without disruptions, maintaining the highest quality standards.

- Innovative Dosage Form Design in Clinical Manufacturing: Our clinical manufacturing capabilities are further enhanced by our innovative dosage form design. We offer a diverse array of formats, ranging from conventional tablets and capsules to more sophisticated multiparticulate systems, each designed to meet the unique needs of our clients and their clinical trials.

Clinical Manufacturing Expertise

- High-Quality Blending and Granulation: In clinical manufacturing, our blending and granulation processes are meticulously optimized. This ensures uniformity and scalability, which are essential for maintaining consistent batch-to-batch quality in the production of pharmaceuticals.

- High-Speed Capsule Manufacturing: Our clinical manufacturing facilities are equipped with high-speed capsule manufacturing equipment. This technology, coupled with 100% weight checking, guarantees precision and efficiency in capsule production.

- Customized Fills for Clinical Trials: The flexibility of our clinical manufacturing services allows us to handle customized fills. This includes the provision of hard gelatin capsules, which are tailored to meet the specific needs of diverse clinical trials.

- Clinical Manufacturing and Controlled Release Formulations: We specialize in creating controlled release formulations within our clinical manufacturing services. This allows for the precise timing of drug release, enhancing therapeutic outcomes.

- Packaging: We are at the forefront of packaging innovation in clinical manufacturing. Our packaging solutions are designed to protect the product, enhance patient convenience, and extend shelf life.

- Supply Chain Optimization: Our clinical manufacturing process includes a focus on supply chain optimization. This ensures the efficient flow of materials and products, reducing lead times and costs.

- Regulatory Strategy: We provide comprehensive regulatory strategy services as part of our clinical manufacturing. This ensures that all products are compliant with global regulatory requirements.

- Stability Studies: Stability studies are a critical component of our clinical manufacturing services. These studies ensure that our products maintain their efficacy and safety throughout their shelf life.

Scale-Up & Distribution

- Efficient Scale-Up Processes in Clinical Manufacturing: Our clinical manufacturing is equipped with rapid scale-up capabilities, ensuring that products seamlessly transition from clinical trials to commercial production, meeting market demands promptly.

- Global Distribution Network and Clinical Manufacturing: Leveraging our global distribution network in clinical manufacturing, we guarantee timely delivery of products, ensuring they reach their destinations efficiently and reliably.

- Clinical Manufacturing and Lifecycle Management: We provide lifecycle management within our clinical manufacturing, ensuring that products are supported from launch through to post-market activities.

Quality & Regulatory Compliance

- GMP-Compliant Facilities: Our clinical manufacturing facilities strictly adhere to Good Manufacturing Practice (GMP) standards, ensuring that every product is consistently produced and controlled according to quality standards.

- Regulatory Support: We offer comprehensive regulatory support as part of our clinical manufacturing services, guiding you through the complex landscape of pharmaceutical approvals to ensure your product complies with all necessary guidelines.

- Data Integrity: Data integrity is a fundamental aspect of our clinical manufacturing operations, ensuring that all data is accurate, reliable, and traceable throughout the product life cycle.

- Robust Quality Systems: Our robust quality systems in clinical manufacturing are designed to comply with regulatory standards, ensuring that every product is safe, effective, and of the highest quality.

Related Services

FAQs

Here are some frequently asked questions about Clinical Manufacturing

Clinical manufacturing services involve the production of investigational medicinal products (IMPs) under Good Manufacturing Practice (GMP) conditions for use in clinical trials. These services encompass the formulation, blending, compounding, filling, and finishing of drug products in various dosage forms, ensuring they meet the required quality standards for safety, stability, and efficacy.

GMP compliance is crucial in clinical manufacturing to ensure that products are consistently produced and controlled according to quality standards. It minimizes risks involved in pharmaceutical production that cannot be eliminated through testing the final product alone, such as cross-contamination, incorrect labeling, and variability in strength. GMP compliance is a legal requirement in the pharmaceutical industry to protect patient safety and maintain the integrity of clinical trial data.

We ensure the quality of clinical trial materials through rigorous quality assurance (QA) and quality control (QC) processes. This includes thorough testing of raw materials, in-process monitoring, and final product testing against predefined specifications. We also implement robust standard operating procedures (SOPs), employee training programs, and state-of-the-art equipment maintenance to uphold the highest quality standards throughout the manufacturing process.

Yes, we can manufacture a wide range of dosage forms, including tablets, capsules, liquids, injectables, topicals, and more. Our facilities are equipped with versatile production lines and controlled environments to handle various formulations, from simple solutions to complex biologics. We work closely with our clients to develop and manufacture the most appropriate dosage form based on the drug's properties and the clinical trial's requirements.

We handle the scalability of clinical manufacturing processes by using scalable equipment and flexible manufacturing strategies that can easily transition from small-scale batches for early-phase trials to larger volumes for late-phase trials and commercialization. Our process development team focuses on scalability during the formulation and process optimization stages to ensure a smooth scale-up and tech transfer, minimizing risks and delays.

We offer comprehensive support for IMP packaging and labeling, including the design and production of patient-friendly packaging, blinding for double-blind studies, and multi-language labeling for global trials. Our services ensure compliance with regulatory requirements, enhance patient compliance, and provide flexibility for randomization and trial design changes.

We manage the supply chain for clinical manufacturing through meticulous planning, coordination with trusted suppliers, and real-time monitoring systems. Our supply chain management includes risk assessment, contingency planning, and maintaining strategic inventory levels to prevent shortages and ensure timely delivery of clinical trial materials.

Yes, we can support the manufacturing of controlled substances for clinical trials. Our facilities are licensed to handle controlled substances, with dedicated secure storage areas and stringent protocols to ensure compliance with regulatory authorities. We implement strict access controls, inventory management, and documentation practices to manage these substances responsibly.

We ensure regulatory compliance across different regions for clinical trials by staying up-to-date with global regulatory standards and requirements. Our regulatory affairs team works closely with clients to navigate the complexities of international regulations, providing expert advice and support for regulatory submissions, audits, and inspections. We tailor our manufacturing processes and documentation to meet the specific needs of each region where the clinical trial will be conducted.

Our post-manufacturing services for clinical trials include stability testing, storage under controlled conditions, distribution logistics, and management of returns and destruction. We also offer data management support for batch records and traceability. These services are designed to maintain the integrity of clinical trial materials throughout the trial lifecycle and ensure compliance with regulatory requirements.