Access efficient jet milling and micronization for your API particles. Discover the benefits of our particle size reduction services applications for oral delivery:

- Improve API dissolution rate to provide sufficient bioavailability of the compound.

- Ensure superior absorption

- Generate API particles for proper delivery

Technology Advantage

Proven, dependable, and extremely versatile, micronization is the most efficient, cost-effective way to achieve top-quality particle size reduction results. Offering a range of technologies for routine, challenging and scheduled compounds, our team offers pharmaceutical micronization methods and services that enhance and advance your compound, with:

Micronization Benefits:

- Proven – leading know-how and established processes – used for decades and well understood by regulators

- Versatile – effective particle size reduction services across a wide range of oral and inhaled products

- Scalable – enabling optimization and control of particle size and distribution, from R&D to commercial scale

- Dependable – producing high yields that consistently exceed alternate particle size technologies

- Precise – using critical process parameters to support regulatory submission expectations

Capabilities

- Micronization

- Mechanical milling

- Cryogenic milling

- Classification

- Comprehensive analytical services

Multiprocessing

When facing exacting particle size requirements, pharmaceutical companies need to partner with a supplier who can offer highly advanced equipment, expertise, and extensive experience. At Hycon, we are committed to improving micronization capabilities for the most challenging particle size specifications and pharmaceutical compounds.

MICRONIZE AND CLASSIFY PHARMACEUTICAL COMPOUNDS

Situated in Central Islip and Happauge in New York, Hycon’s multi-processing classifier mills provides distinctive and specialized solutions for micronizing and classifying powders. It stands out by ensuring an exceptionally narrow particle size distribution, surpassing conventional methods of micronization or milling. The versatility of this system makes it ideal for formulations that demand precise reduction of both fine and large particles.

HOW PARTICLE SIZE CLASSIFIERS WORK

Conventional spiral jet micronizers utilize centrifugal forces to regulate particle size. However, at Hycon, our pharmaceutical multi-processor adopts an integrated ultrafine classifier wheel, providing precise control over particle size during the milling process.

- Typical application area: Our technology caters to all pharmaceutical materials that demand a narrow particle size distribution, including suspensions, and modified-release applications.

- Typical size range: Achieving a d97 of 4μm, with a d50 approximately 2μm.

- Batch size: From 400g and up

Quality By Design

We develop screening and optimization Design of Experiment (DOE) protocols and conduct well-defined milling/micronization runs. We also provide insightful risk assessment to custom develop the optimal design space for our client’s product. Our QbD offerings are part of a dedicated approach to customer support, to fuel continuous process improvements, cost savings, and regulatory flexibility.

Cryogenic Micronization

Cryogenic micronization, using a liquid nitrogen-chilled air-jet mill, is ideal for hard-to-process compounds at room temperature. Hycon’s Cryogenic Air-Jet Mill offers flexibility for various batch sizes and adapting to both large and small production needs.

This advanced technique operates at temperatures as low as -50ºC, unlike traditional room temperature methods. This extreme cold makes compounds more brittle, allowing for finer particle sizes unachievable in normal conditions, enhancing precision in challenging formulations.

Bioavailability Solutions

Hycon can support your R&D teams earlier in the development cycle with a set of bioavailability solutions.

From API optimization, particle size optimization and formulation services, to drug delivery technology selection and final dose form design services; Hycon can help you at the earliest stages of the drug development process. Our team can provide end-to-end solutions to accelerate your programs to clinic and to market, utilizing our broadest expertise, best technologies and rigorous science, including:

- API screening and optimization platform

- Selection Tool for optimal finished dose

- Preformulation/Formulation expertise including:

- Particle size engineering

- Optimal oral dose development

- Softgel

- Hot melt extrustion

- Clinical packaging and integrated clinical supply solutions

- Global clinical and commercial manufacturing capabilities

Selecting a Particle Size Test

- cGMP laboratories

- Particle size distribution analysis

- Sieve analysis

- Study design guidance

- Full release testing for commercial projects

Working Towards Development Goals

At Hycon, we have extensive experience in developing and validating methods for drug characterization. Our characterization testing helps you with a wide array of development decisions including:

- Determining optimal particle size

- Selecting appropriate milling technology

- Troubleshooting formulation issues

- Optimizing processing conditions (e.g., milling conditions, humidity, temperature, etc.)

Our extensive analytical capabilities help simplify your supply chain, reduce overall costs and fast track time-to-market.

Analytical Services

Our analytical services encompass a full range of particle size characterization techniques:

- Particle Size Analysis by Laser-Diffraction

- X-ray Powder Diffraction (XRD)

- Differential Scanning Calorimetry (DSC)

- Thermogravimetric Analysis (TGA)

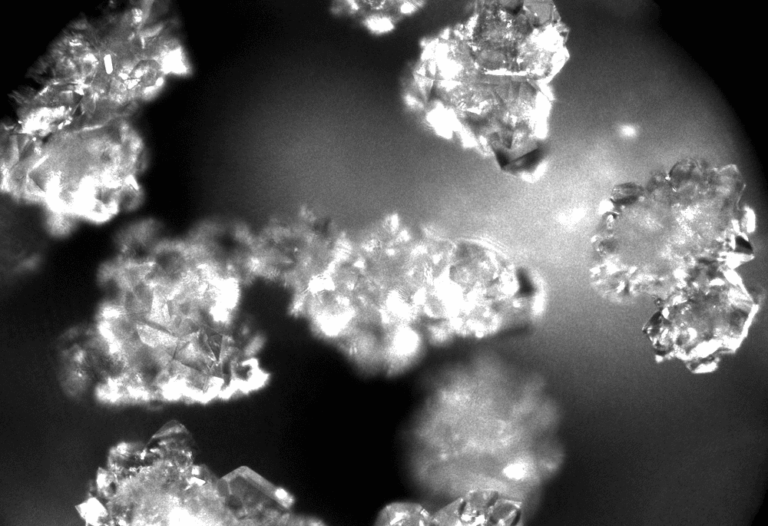

- Scanning Electron Microscopy (SEM) and Optical Microscopy

- Surface Area Analysis

- Dynamic Vapor Sorption (DVS)

- HPLC and GC

- Dissolution

- Karl Fischer Titration

- Stability Testing and Sample Storage

- Release Testing

Learn more about the breadth of analytical services to support rapid product development by visiting our Small Molecule Analytical Chemistry pages.

In-Process Particle Size Analysis

Operational parameters are monitored throughout the size reduction process to help adjust and improve the milling parameters. During this process they are analyzed to ensure the targeted specification is being delivered. Based on these measurements the milling conditions are adjusted to generate micronized material with an acceptable micron size. Upon completion, the material is released as per specification. All projects are accompanied by a comprehensive batch record and particle size results from the in-process analysis.

Process Validation Design

Based upon solid regulatory, analytical, and manufacturing knowledge, Hycon works with you to develop a validation plan tailored to your needs. Our robust and efficient validation services comply with cGMP guidelines. Support of the validation process also includes protocol development and execution. Final reporting of this process will help carry your project into its commercial phase.

Particle Size Reduction

Particle size reduction is an important material engineering to improve bioavailability and achieve certain specifications . The micronization process generates a more consistent particle size distribution, thereby enhancing pharmaceutical formulations. To satisfy cGMP guidelines and deliver results, scientists must seek particle size reduction services that use specialized equipment, while offering support for customized protocol development, validation, execution and reporting.

Effective particle size reduction requires an understanding of many material characteristics, including particle size distribution, hardness and flowabilty. Formulations may also require specialized protocols based on the potency of the active ingredients. Hycon works to understand the requirements of your formulations, with robust particle size testing and analyses. This knowledge is then passed to you as part of a final project report.

Fundamental Concept

- Micronization is a critical pharmaceutical process that reduces the particle size of solid drug substances to the micrometer scale, typically below 10 microns in diameter.

- This size reduction is achieved through high-pressure air or other gases in jet mills, or through mechanical mills.

Significance in Drug Development

- The process is vital for enhancing the bioavailability of drugs with poor solubility, a common issue with many small-molecule drugs.

- By increasing the surface area of the drug particles, micronization improves the dissolution rate, which is essential for oral bioavailability.

Micronization Process

Technological Implementation

- Hycon employs advanced micronization technologies, including jet milling and mechanical milling, to achieve precise particle size distributions.

- The choice of technology depends on the physical and chemical properties of the drug substance and the desired final product specifications.

Process Optimization

- Hycon scientists meticulously optimize the micronization process parameters, such as feed rate and milling pressure, to ensure consistent particle size distribution and high product quality.

- They also focus on minimizing any potential thermal degradation of the drug substance during the process.

Technologies

Jet Milling

- Jet milling is a common method where high-velocity compressed air or inert gas is used to collide particles against each other, leading to particle size reduction.

- Hycon utilizes fluidized bed jet mills, which allow for precise control over the final particle size distribution and minimize product contamination as the mechanics of the jet mill remove the need for any grinding media.

High-Pressure Homogenization

- This technique subjects a liquid suspension of the drug to very high pressures, forcing it through a narrow gap to reduce particle size.

- Hycon employs high-pressure homogenizers that are capable of producing uniform sub-micron particles.

Mechanical milling is focuses on uniform particle sizes above 20 microns. This process enhances particle uniformity, distribution, and the effectiveness of compounds. Mechanical milling processes are optimized to prevent thermal degradation of heat-sensitive APIs during size reduction. During the manufacturing process we pay careful attention to blend consistency and optimized release profiles, backed with extensive analytical support.

- Hammer Mill: Our high-throughput hammer mills are designed for diverse size-reduction needs, from delumping to fine grinding, with interchangeable screens for ultimate control.

- Pin Mill: The pin mill’s screenless operation provides consistent size reduction, achieving finer results than traditional hammer mills through a stationary and rotating plate mechanism.

- Conical Mill: As an alternative to hammer or other mills, our conical mill utilizes a rotating impeller to force material through a conical screen, ensuring uniform size reduction.

Benefits

Enhanced Dissolution Rates

Surface Area to Volume Ratio

- Micronization significantly increases the surface area to volume ratio of drug particles, which is directly proportional to the dissolution rate in biological fluids.

- Hycon scientists utilize precision-engineered milling equipment to achieve the optimal increase in surface area, ensuring rapid dissolution.

Solubility Enhancement

- For drugs with poor solubility, particularly those classified as BCS class II, micronization can be a game-changer by enhancing their solubility profile.

- The team at Hycon carefully selects milling conditions that preserve the drug’s crystalline structure while achieving the desired particle size.

Improved Bioavailability

Absorption Efficiency

- Smaller particles created through micronization have a higher probability of being absorbed efficiently in the gastrointestinal tract, leading to improved bioavailability.

- Hycon’s formulation experts work to balance particle size reduction with the preservation of drug efficacy and stability.

Therapeutic Effectiveness

- By enhancing bioavailability, micronization helps in achieving the desired therapeutic effect with potentially lower doses of the API.

- Hycon’s scientists conduct thorough in vitro and in vivo studies to confirm the improved bioavailability of micronized formulations.

Uniform Particle Size Distribution

Dosing Accuracy

- A uniform particle size distribution is crucial for accurate dosing, which is essential for the efficacy and safety of pharmaceutical products.

- Hycon employs advanced particle size analysis techniques to ensure that each batch of product meets stringent uniformity standards.

Consistency in Formulations

- Consistent particle size is key to the homogeneity of the final pharmaceutical formulation, affecting both the manufacturing process and the end-user experience.

- The quality control teams at Hycon rigorously test for particle size distribution to guarantee consistency across all product batches.

Milling

Integration of Milling in Hycon CDMO’s Services

- From Concept to Market: Milling is integral from the initial development stages of a drug, aiding in the creation of consistent and bioavailable formulations, through to large-scale commercial manufacturing.

- Enhanced Drug Formulation: Our milling services are crucial for optimizing the physical properties of APIs, which is essential for the successful formulation of oral dosage forms.

The Role of Milling in Drug Development

- Preformulation Studies: Milling is employed during preformulation to obtain the desired particle size that ensures uniformity and stability in the final dosage form.

- Formulation Development: It plays a pivotal role in the development phase, where the milled particles are tested for compatibility with other formulation components.

Milling in Clinical and Commercial Manufacturing

- Clinical Trial Materials: Milling is used to produce clinical trial materials, ensuring that the drug substances exhibit the necessary bioavailability and stability.

- Commercial Scale-Up: As projects move to commercial scale, milling processes are optimized for mass production while maintaining stringent quality standards.

Hycon Scientists’ Approach to Milling

- Process Design and Optimization: Hycon scientists design and optimize the milling process using a data-driven approach, ensuring reproducibility and scalability.

- Material Characterization: Before milling, scientists characterize the physical and chemical properties of the API to determine the most suitable milling technique.

- Equipment Selection: Depending on the API characteristics, scientists select the appropriate milling equipment, such as jet mills or hammer mills, to achieve the desired particle size.

- Parameter Control: Critical process parameters, such as feed rate, milling speed, and temperature, are tightly controlled to ensure consistent particle size distribution.

- Analytical Testing: Post-milling, the particle size distribution is analyzed using sophisticated techniques to confirm that the product meets all specifications.

- Continuous Improvement: Our scientists engage in continuous improvement practices, applying the latest research and technological advancements to enhance the milling process.

Process

Material Assessment

- API Characterization: Scientists begin by thoroughly characterizing the Active Pharmaceutical Ingredient (API), determining its physical and chemical properties to inform the milling process.

- Milling Process Optimization: They employ various milling techniques to achieve the desired particle size and distribution, which is crucial for the drug’s bioavailability and stability.

- Formulation Strategy: Hycon formulates the milled API into oral dosage forms, considering factors like solubility, stability, and patient acceptability.

Process Design

- Customized Protocols: Based on the material assessment, scientists develop customized milling protocols, considering the unique requirements of each API.

- Equipment Selection: They choose the most suitable milling equipment, ensuring that the selected technology can achieve the desired particle size and distribution.

Manufacturing and Scale-Up:

- Process Validation: Before scaling up, the milling process is validated to ensure it can consistently produce high-quality milled particles.

- Equipment Calibration: Milling equipment is calibrated to handle the specific requirements of the API, ensuring optimal output.

- Batch Manufacturing: Scientists oversee the batch manufacturing process, ensuring that each step meets the stringent standards set by regulatory authorities.

Milling Execution

- Parameter Optimization: Our scientists fine-tune the milling parameters, such as feed rate and milling speed, to obtain the optimal particle size.

- Real-Time Monitoring: The milling process is monitored in real-time, allowing scientists to make immediate adjustments to maintain the desired output.

Quality Assurance & Control

- Particle Size Analysis: Post-milling, the particle size is rigorously analyzed to ensure consistency and uniformity across batches.

- Consistency Verification: Scientists perform consistency checks to ensure that the milled product will contribute to a uniform final dosage form.

- Bioavailability Studies: Scientists conduct in vitro and in vivo studies to assess the bioavailability of the milled API, comparing it against standard formulations.

- Stability Testing: Long-term stability tests are performed to ensure that the milled particles maintain their efficacy throughout the product’s shelf life.

Final Product Preparation

- Integration into Formulation: The milled particles are carefully integrated into the drug formulation, maintaining the integrity of the active pharmaceutical ingredient.

- cGMP Compliance: Throughout the process, adherence to cGMP standards is maintained to ensure the final product is of the highest quality.

Regulatory Compliance:

- Documentation: Comprehensive documentation is maintained throughout the development process to meet regulatory requirements.

- Audits and Reviews: Regular audits and reviews are conducted to ensure compliance with Good Manufacturing Practices (GMP) and other regulatory standards.

Customization & Scalability

Customized Milling Services for Different APIs:

- API-Specific Parameters: Hycon tailors milling parameters such as speed, duration, and temperature to the physical and chemical characteristics of each API.

- Particle Size Optimization: The desired particle size distribution is achieved by adjusting the milling process, which can significantly affect the drug’s solubility and bioavailability.

- Equipment Flexibility: A range of milling equipment is available to accommodate different APIs, from mechanical mills to micronizers and homogenizers.

- Co-Micronization: For APIs with poor solubility, Hycon offers co-micronization with excipients to enhance dissolution rates and bioavailability.

Scalability of the Milling Process:

- Small Batch Production: Hycon’s milling services are designed to be scalable, starting from small-scale batches suitable for R&D and clinical trials.

- Large Scale Manufacturing: The process can be scaled up to large batch production, maintaining the same quality and particle size distribution as the small-scale batches.

- Process Validation: Each step of the scale-up process is validated to ensure consistency and compliance with regulatory standards.

Related Services

FAQs

Here are some frequently asked questions about Micronization & Milling

Micronization is a process used to reduce the particle size of solid materials to micron or sub-micron levels, typically below 10 microns. This process is achieved through high-energy air jet mills or mechanical mills, enhancing the solubility, absorption, and bioavailability of drugs. Micronization is especially beneficial for active pharmaceutical ingredients (APIs) with poor water solubility, as smaller particle sizes increase the surface area, leading to better dissolution rates in the body.

Micronization improves drug formulation by increasing the surface area of the drug particles, which enhances their dissolution rate in biological fluids. This can lead to higher bioavailability, allowing the drug to reach its therapeutic effect more quickly and efficiently. Additionally, micronization can aid in achieving uniform particle size distribution, improving the stability and homogeneity of suspensions and ensuring consistent drug dosing in solid dosage forms.

The main difference between micronization and milling lies in the particle size achieved and the mechanism used for size reduction. Micronization refers specifically to reducing particle sizes to the micron or sub-micron level, typically using air jet mills or high-energy processes. Milling, on the other hand, encompasses a broader range of particle size reductions and may use mechanical mills, such as ball mills or hammer mills, to produce particles that are larger than those produced by micronization. Milling is versatile and can be used for a variety of purposes, including initial size reduction, granulation, and coarse grinding.

We offer a comprehensive range of milling services tailored to meet diverse formulation and production needs, including:

- Cryogenic milling: For heat-sensitive materials, utilizing liquid nitrogen to prevent thermal degradation during milling.

- Wet milling: For producing stable suspensions or nanoemulsions.

- Dry milling: Suitable for most solid materials, providing a cost-effective and straightforward size reduction solution.

- Fine and ultra-fine milling: For achieving very small particle sizes, crucial for enhancing drug solubility and bioavailability.

Yes, we are equipped to handle high-potency compounds with stringent containment measures to ensure the safety of our personnel and prevent cross-contamination. Our facilities are designed with advanced engineering controls, including isolated milling chambers and dedicated air handling systems. We also employ rigorous cleaning protocols and personal protective equipment (PPE) requirements to manage the risks associated with high-potency API processing.

Our quality control measures for micronization and milling include:

- Particle size analysis: Utilizing laser diffraction, sieve analysis, or other relevant techniques to ensure target particle size distribution is achieved.

- Process monitoring: Continuous monitoring of process parameters to maintain operational consistency and product quality.

- Cross-contamination prevention: Implementing strict cleaning protocols and equipment segregation to prevent cross-contamination.

- GMP compliance: Ensuring all operations comply with Good Manufacturing Practices, including documentation and traceability of all materials and processes.

We ensure the reproducibility of our micronization and milling processes through standardized operating procedures (SOPs), meticulous calibration and maintenance of equipment, and rigorous training of our personnel. Process parameters such as feed rate, air pressure (for jet mills), and milling time are carefully controlled and documented to guarantee consistent particle size distribution and quality across batches. Additionally, we conduct validation studies to confirm that our processes are stable and capable of producing the desired outcomes reliably.

A wide range of materials are suitable for micronization and milling, including active pharmaceutical ingredients (APIs), excipients, and intermediates. These processes are particularly beneficial for materials that require size reduction to enhance solubility, bioavailability, or physical stability. Our services are applicable to both organic and inorganic compounds, and we can accommodate materials with various properties, including heat sensitivity and hygroscopicity, by selecting the most appropriate milling technique.

The optimal particle size for a given drug is determined based on its physicochemical properties, the intended route of administration, and the desired release profile. We conduct pre-formulation studies, including solubility and dissolution testing, to evaluate how particle size affects the drug's performance. Collaborating closely with our clients, we consider the therapeutic goals and regulatory requirements to define the target particle size distribution that will achieve the optimal balance between bioavailability, stability, and manufacturability.

Our micronization and milling services are scalable to meet the demands of both development-stage projects and commercial-scale production. We have a range of milling equipment that can handle batch sizes from small-scale pilot batches for clinical trials to large-scale manufacturing runs. Our team works with clients to plan and execute milling campaigns that align with their production timelines and volume requirements, ensuring flexibility and efficiency in meeting their needs.