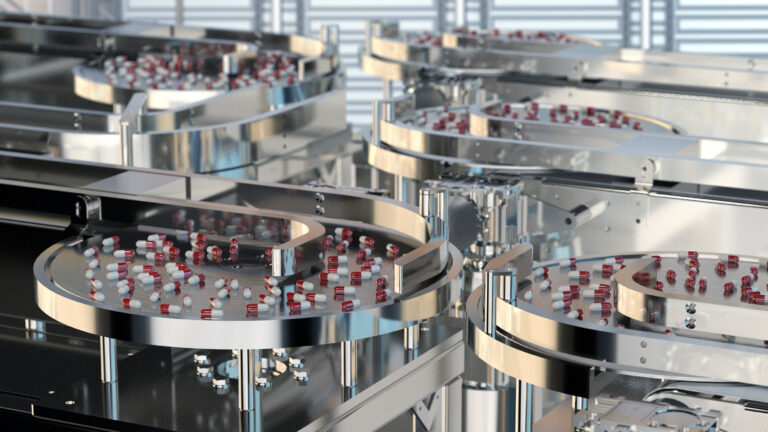

Finished Dosage Forms (FDF) represent the final consumable product provided to patients, encompassing tablets, capsules, injectables, and topical formulations. The production of these forms is the culmination of extensive research, development, and manufacturing processes. In the pharmaceutical industry, Contract Development and Manufacturing Organizations (CDMOs) are crucial, offering specialized services to efficiently and cost-effectively bring these finished products to market.

The Role of CDMOs in the Pharmaceutical Industry

CDMOs provide a comprehensive range of services that cover the entire lifecycle of a drug product, from initial development to commercial production. These organizations offer expertise in formulation development, analytical testing, clinical trial manufacturing, and large-scale commercial manufacturing. By collaborating with CDMOs, pharmaceutical companies can focus on their core competencies, leveraging the specialized capabilities of CDMOs to accelerate time-to-market and reduce costs.

Key Services Offered by CDMOs for Finished Dosage Forms

- Formulation Development: CDMOs work closely with pharmaceutical companies to develop robust and scalable formulations. This includes pre-formulation studies, excipient compatibility testing, and optimization of the drug delivery system. Their expertise ensures that the final product is effective, safe, and stable.

- Analytical Testing: Comprehensive analytical testing is vital to guarantee the quality, safety, and efficacy of finished dosage forms. CDMOs provide in-house analytical services, including method development, validation, and stability testing. These services ensure that products meet regulatory standards and maintain their intended performance over time.

- Clinical Trial Manufacturing: CDMOs support the production of clinical trial materials, ensuring that investigational products meet regulatory standards and are available in sufficient quantities for clinical studies. This phase is critical for the success of clinical trials and the subsequent approval of the drug product.

- Commercial Manufacturing: Once a drug product receives regulatory approval, CDMOs scale up production to meet commercial demand. This involves large-scale manufacturing, packaging, and distribution. CDMOs ensure that the transition from clinical to commercial production is seamless and efficient.

Semi Solids Formulation Development

- Advanced Microencapsulation Techniques: Utilizing cutting-edge microencapsulation, we safeguard APIs from degradation, precisely control release rates, and mask any unpleasant tastes or odors. This technique is essential in semisolid and gel formulations, where the encapsulated APIs are released at targeted sites, optimizing therapeutic benefits while minimizing systemic exposure.

- Smart Polymer Systems: Our smart polymer systems are integral to semisolids and gels, reacting to physiological triggers like pH shifts, temperature changes, or enzymatic actions. These systems ensure a more controlled drug release from semisolids, adapting in real-time to the body’s varying conditions.

- Enhanced Skin Permeation: To improve the efficacy of topical semisolids and gels, we focus on enhancing skin permeation. Strategies include the use of penetration enhancers and lipid-based nanocarriers, which aid in transporting APIs through the skin barrier more effectively.

- Customized Formulation Development: We tailor each semisolid and gel formulation to the specific needs of the API and therapeutic goals. Our collaborative approach with clients ensures the development of formulations that are not only therapeutically effective but also offer a pleasing aesthetic and feel.

Types of Finished Dosage Forms

- Solid Dosage Forms: Tablets and capsules are the most common solid dosage forms, offering convenience, stability, and precise dosing. CDMOs provide expertise in the formulation and manufacturing of various solid dosage forms, including immediate-release, controlled-release, and orally disintegrating tablets. Their knowledge ensures that these products meet patient needs and regulatory requirements.

- Semi-Solid Dosage Forms: This category includes creams, ointments, gels, and suppositories. Semi-solid dosage forms are used for topical and rectal administration. CDMOs offer formulation development and manufacturing services for a wide range of semi-solid products, ensuring their effectiveness and safety.

- Liquid Dosage Forms: Solutions, suspensions, and emulsions fall under this category. Liquid dosage forms are used for oral, parenteral, and topical administration. CDMOs provide expertise in the formulation and sterile manufacturing of liquid dosage forms, ensuring their stability and efficacy.

Advantages of Partnering with CDMOs

- Cost Efficiency: Outsourcing to CDMOs allows pharmaceutical companies to reduce capital expenditure on manufacturing facilities and equipment. CDMOs provide cost-effective solutions by leveraging their existing infrastructure and expertise. This approach minimizes financial risk and optimizes resource allocation.

- Speed to Market: CDMOs have the experience and resources to expedite development and manufacturing processes, enabling faster time-to-market for new drug products. This speed is crucial in the competitive pharmaceutical industry, where timely product launches can significantly impact market success.

- Regulatory Compliance: CDMOs are well-versed in regulatory requirements and ensure that all processes and products meet the necessary standards. This reduces the risk of regulatory delays and non-compliance, providing peace of mind to pharmaceutical companies and safeguarding public health.

- Flexibility and Scalability: CDMOs offer flexible manufacturing solutions that can be scaled up or down based on demand. This flexibility allows pharmaceutical companies to respond quickly to market changes and product demand, ensuring that they can meet customer needs efficiently and effectively.

Related Services