Fixed Dose Combinations (FDCs) are medications that contain two or more active ingredients in a single dosage form, such as a capsule or tablet. This strategy is aimed at enhancing patient adherence, optimizing therapeutic efficacy, and potentially minimizing drug resistance. This can be particularly beneficial for treating chronic conditions where patients might otherwise have to manage multiple medications with different dosing schedules.

FDCs are designed to deliver each active ingredient in a fixed ratio, and they can be used to target a single disease or multiple conditions. For example, some over-the-counter FDCs are used to treat motion sickness and nausea, while prescription FDCs can be used for conditions like attention deficit hyperactivity disorder (ADHD), narcolepsy, and even complex diseases like HIV/AIDS.

Pharmacokinetics (PK) in FDCs

Absorption Dynamics

The absorption of drugs within an FDC is influenced by the physicochemical properties of each API, such as solubility and stability. The design of the FDC formulation must ensure that each API is released at a rate that allows for optimal absorption without interference from the other components. For example, if one API requires an acidic environment for absorption while another is degraded in acid, the formulation must balance these conflicting requirements.

Distribution and Its Complexities

After absorption, the APIs must reach their intended sites of action. This involves navigating the body’s complex vascular and tissue networks. Factors such as lipid solubility, molecular size, and the presence of transport proteins can greatly influence the distribution of each API. Additionally, the potential for drug-drug interactions within the FDC that could alter distribution must be carefully evaluated.

Metabolism: Enzymatic Interactions and Consequences

The metabolism of APIs in an FDC can be significantly different from their metabolism when administered separately. The liver’s cytochrome P450 enzymes play a crucial role in drug metabolism, and the presence of multiple APIs can lead to competitive inhibition or enzyme induction, potentially leading to altered levels of the drugs and their effects.

Elimination: Renal and Hepatic Considerations

The elimination of drugs in an FDC is a critical aspect of their PK profile. The kidneys and liver are the primary organs involved in drug elimination, and their function must be considered when designing an FDC. For instance, if one API is primarily eliminated by the kidneys, its presence should not impair the renal elimination of another API within the same FDC.

Delving into Pharmacodynamics (PD) in FDCs

Receptor Binding and Response Modulation

The PD of an FDC is determined by the interactions of the APIs with their respective receptors. The goal is to achieve a therapeutic effect that is greater than the sum of the individual effects of each API. This can involve agonist-antagonist interactions, receptor downregulation, or upregulation, and must be finely tuned to avoid adverse effects.

Enzyme Inhibition and Activation

In some FDCs, one API may act as an enzyme inhibitor, enhancing the effect of another API by slowing its metabolism. Conversely, an API might act as an enzyme activator, increasing the metabolic rate of another component. These interactions must be understood and controlled to achieve the desired therapeutic outcome.

Non-Receptor Mediated Actions

Some APIs in an FDC may exert their effects through non-receptor mediated pathways, such as by altering biochemical pathways or affecting gene expression. These actions must be harmonized within the FDC to ensure that they do not counteract each other and that they contribute positively to the overall therapeutic effect.

Dose-Response Curves and Therapeutic Windows

The dose-response relationship in an FDC is complex, as it involves the combined effects of multiple APIs. The therapeutic window, the range of doses that produces a therapeutic effect without causing significant side effects, must be carefully established for the FDC as a whole, taking into account the interactions between the APIs.

Dose Determination Strategies for FDCs

Standard Dose Strategy

The standard dose strategy is typically employed for medications where a uniform dose is suitable for the majority of the patient population. This approach simplifies manufacturing and prescribing practices. However, it may not account for individual variations such as genetic factors, comorbidities, or concurrent medications that could affect drug metabolism and response.

Adjusted Dose Strategy

Adjusted doses are tailored based on measurable physiological functions or biomarkers. This strategy is particularly relevant for medications that have a narrow therapeutic index or require individualized dosing to achieve optimal therapeutic outcomes. It allows for personalization of therapy but can be more complex to manage, especially in an FDC format.

Target Concentration Dose Strategy

This strategy involves maintaining plasma drug concentrations within a specific therapeutic range. It is often used for drugs with complex pharmacokinetics or where the therapeutic effect is not directly observable. The challenge lies in monitoring drug levels and adjusting doses accordingly, which can be difficult in an FDC due to the fixed ratios of APIs.

Calibrated Dose Strategy

Calibrated doses are used when the maximum efficacy of a drug might lead to intolerable side effects. This is often seen in oncology, where dosing must be carefully managed to balance the cytotoxic effects against the potential for severe adverse reactions. The calibrated dose strategy requires close monitoring and may involve dose adjustments based on patient response and tolerance.

Food Interaction Considerations

Food interactions can significantly affect the absorption and bioavailability of drugs in an FDC. For instance, certain drugs may need to be taken with food to enhance absorption or reduce gastrointestinal side effects. The formulation of an FDC must take into account these interactions to ensure consistent drug delivery and therapeutic effect.

Dose Flexibility Challenges

FDCs offer the advantage of simplified dosing regimens, which can improve patient adherence. However, they also present challenges in terms of dose flexibility. Unlike single-drug formulations, it is difficult to adjust the dose of individual components in an FDC without affecting the overall balance of the combination. This can be particularly problematic when treating populations with varying pharmacokinetic profiles or when dose titration is necessary.

Patient-Centric Approach

A patient-centric approach to dose determination considers the patient’s lifestyle, preferences, and ability to adhere to the treatment regimen. This approach aims to optimize the therapeutic experience by making medication regimens more convenient and less burdensome, thereby improving adherence and overall health outcomes.

Economic and Manufacturing Considerations

Economic and manufacturing considerations also play a role in dose determination. The cost-effectiveness of producing an FDC, as well as the feasibility of manufacturing processes, can influence the choice of dose strategies. Balancing these considerations with clinical efficacy and safety is crucial for the successful development and market acceptance of an FDC.

Addressing Customer Needs

In-Depth Analysis of Therapeutic Needs

The development of FDCs begins with a thorough understanding of the therapeutic landscape. This includes an in-depth analysis of the disease’s epidemiology, pathophysiology, and the current treatment protocols. It’s essential to identify the gaps in existing therapies and how an FDC can bridge these gaps by offering a more effective or convenient treatment option. The design of an FDC must be rooted in solid clinical evidence that demonstrates the benefits of combining specific drugs to treat a particular condition.

Comprehensive Patient Demographics Study

A detailed study of patient demographics is critical for the success of an FDC. This study should encompass a wide range of data, including age distribution, gender differences, genetic variations, and comorbidities that may affect the drug’s efficacy and safety profile. Such a study ensures that the FDC is suitable for the broadest possible patient population while also allowing for the identification of subgroups that may require tailored dosing regimens.

Tailoring Treatment Outcomes

The ultimate goal of any pharmaceutical intervention is to improve patient outcomes. In the context of FDCs, this means not only managing the disease effectively but also enhancing the patient’s quality of life. This could involve reducing the pill burden, minimizing side effects, and ensuring that the treatment is affordable and accessible. The FDC must be designed with these outcomes in mind, ensuring that it aligns with the patient’s lifestyle and preferences.

Balancing Convenience with Customization

While FDCs offer the convenience of reduced pill burden, they must also maintain the flexibility to adjust dosages according to individual patient needs. This is particularly important for drugs with a narrow therapeutic index or for populations such as the elderly or those with renal impairment. The design of the FDC should allow for dose adjustments without compromising the integrity of the combination therapy.

Utilizing Cutting-Edge Formulation Technologies

The development of FDCs often involves cutting-edge formulation technologies to optimize the delivery and performance of the combined drugs. These technologies include, but are not limited to, bilayer systems, active film coating, co-crystals, multi-particulate systems, and 3D-printing. Each technology offers unique advantages in terms of controlling drug release, enhancing stability, and improving patient adherence.

Navigating Regulatory Landscapes

Regulatory considerations are paramount in the development of FDCs. Developers must navigate a complex landscape of guidelines and requirements to ensure that their FDC is approved for clinical use. This includes demonstrating the scientific rationale behind the combination, providing evidence of clinical benefit, and ensuring that the product meets all safety standards. Regulatory agencies may require extensive data on pharmacokinetics, pharmacodynamics, and clinical outcomes to approve an FDC.

Ethical and Economic Considerations

Beyond the scientific and regulatory aspects, ethical and economic considerations also play a significant role in FDC development. Ethically, the FDC must be developed with the patient’s best interest in mind, ensuring that it provides a real therapeutic advantage over existing treatments. Economically, the FDC should be cost-effective, not only in terms of production and distribution but also in terms of the economic burden on the healthcare system and the patient.

Regulatory and Clinical Landscape for FDCs

Regulatory Framework

The regulatory framework for FDCs is complex, involving multiple guidelines and requirements that vary by country and region. Regulatory bodies enforce stringent standards to ensure that FDCs are safe, effective, and manufactured to the highest quality.

- FDA: The FDA’s approach to FDCs is rigorous, requiring substantial evidence of safety and efficacy. The agency evaluates the rationale for combining APIs, the potential for drug-drug interactions, and the suitability of the combination for the intended patient population.

- CDSCO: India’s CDSCO has a detailed classification system for FDCs based on their origin status. The organization has implemented rules under Schedule Y and the New Clinical Trials Rules 2019, which dictate the requirements for clinical trials and market approval of FDCs.

Clinical Trial Design and Execution

Clinical trials for FDCs are meticulously designed to meet regulatory standards. These trials must address:

- Efficacy and Safety: Trials must show that the FDC provides a therapeutic advantage over monotherapy or separate administration of the APIs.

- Pharmacokinetics and Pharmacodynamics: Studies must assess how the drugs interact with each other and with the body to determine appropriate dosing regimens.

Post-Marketing Surveillance

After an FDC is approved, it undergoes post-marketing surveillance to monitor its long-term safety and effectiveness. This phase is crucial for detecting any adverse effects not observed during clinical trials and for ensuring ongoing patient safety.

Regulatory Challenges

Regulatory bodies face challenges in enforcing the marketing of FDCs, particularly in regions where the manufacture of large numbers of FDCs occurs without the required prior approval. Efforts to address these issues include major regulatory initiatives aimed at removing unapproved FDCs from the market.

Harmonization Efforts

International harmonization efforts, such as those by the ICH, aim to standardize regulatory requirements to facilitate the development and approval of FDCs globally. This helps in reducing duplication of clinical trials and expediting access to essential medications.

Future Directions

The future of FDC regulation may involve more personalized approaches, considering patient-specific factors and genetic profiles. Additionally, real-world evidence and patient-reported outcomes are becoming increasingly important in supporting regulatory decisions and ensuring that FDCs meet the evolving needs of healthcare.

Manufacturing and Quality Assurance

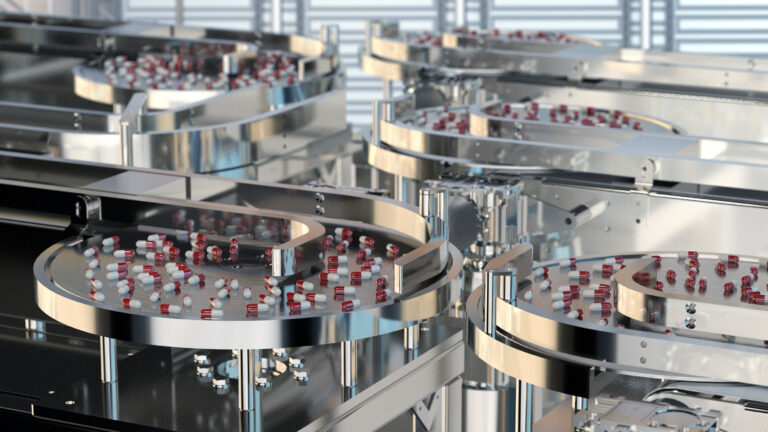

Challenges in Production

The production of Fixed-Dose Combinations (FDCs) is a sophisticated endeavor that requires meticulous attention to detail to ensure the uniform distribution of Active Pharmaceutical Ingredients (APIs). The challenges are multifaceted, involving the assurance of chemical compatibility between APIs to prevent adverse interactions that could compromise the stability and efficacy of the combined medication. The process must also address the solubility and therapeutic dose requirements of each API, which necessitates a careful balance to achieve the desired pharmacokinetic profile. Furthermore, the physical characteristics of the dosage form, such as size and shape, must be considered to facilitate ease of administration while avoiding drug-drug interactions that could affect patient safety.

Quality Control Measures

Quality control (QC) is a critical component in the manufacturing of FDCs. It encompasses a series of stringent testing protocols to verify the accuracy and consistency of each API’s dosage within the FDC. This rigorous approach ensures that the final product not only adheres to the established potency specifications but also aligns with regulatory compliance standards. The QC process is supported by a comprehensive documentation system that records every aspect of the manufacturing process, thereby providing a traceable account of the product’s journey from raw materials to finished goods.

Market Analysis

Successful FDCs in the Market

The landscape of successful FDCs is marked by products that have significantly enhanced patient adherence and treatment outcomes, particularly in the management of chronic conditions such as HIV/AIDS. These FDCs have demonstrated their value by simplifying treatment regimens, reducing the number of pills patients must take, and improving overall therapeutic effectiveness. The success stories of these FDCs serve as a testament to the potential of combination therapies in achieving better patient outcomes.

Market Trends and Patient Preferences

The FDC market is currently experiencing a trend towards oral solid dose (OSD) platforms, which are favored for their convenience and dosing flexibility. This shift is driven by patient-centric considerations, with a focus on improving adherence to treatment regimens. The market analysis reveals a growing preference for FDCs due to their ability to enhance therapeutic effects, reduce the likelihood of resistance development in infectious diseases, and support long-term therapy adherence. The evolving preferences underscore the importance of patient convenience and the potential of FDCs to meet the needs of diverse patient populations.

Related Services